Concordia Corner

Tactile understanding

yury yuryev

For the visually impaired, a white cane is a window on the world. Its rhythmic sweep and tap provides information about the texture, depth and hardness of a surface, allowing people to confidently navigate down streets, onto buses and around obstacles.

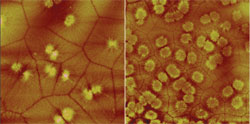

As Paula Wood-Adams (Mechanical and Industrial Engineering) explained, an atomic force microscope (AFM) can work in a similar fashion to further work in her Laboratory for the Physics of Advanced Materials studies materials. “We tap the tip of its sensor close to the surface under study to learn about a material’s properties and structures.”

The AFM is a tactile, not visual, microscope which allows for the study of the extremely small. Its resolution is limited only by the size of its sensors rather than diffraction effects of lenses. And the resolution is rather good. As research assistant Ark Fatseyeu described, “It isn’t sensitive enough to feel individual atoms, but it can feel the spaces between them.”

Wood-Adams said that while the AFM can work on the atomic level of nanometers (billionths of a meter), she and her research team are using it more at the molecular level of micrometres (millionths of a meter). Her lab studies materials, such as experimental polymers, which due to their cost or difficulty of production are often only available in very small amounts.

“We can also study materials that are pretty standard, but awkward to examine otherwise,” such as the incredibly thin polymer coating applied to the aluminum of soft drink cans.

The AFM has interchangeable sensor tips, one of which is specialized to provide a measure of a material’s strength, hardness, toughness, elasticity, plasticity, brittleness, ductility and/or malleability. In one trial Wood-Adams was trying to determine the hardness of a polymer by scratching its surface with an AFM sensor. The result was a tiny, perfect and measurable trough in the material’s surface.

“We also use it to measure the properties of crystalline polymer structures we grow in the lab,” she explained.

The AFM was purchased about five years ago with a CFI grant. “At the time, it was a pretty amazing thing,” she said. Now there are two in the university (the other is over at Loyola in Louis Cuccia’s lab in the Department of Chemistry & Biochemistry) and the “AFM has become standard for nano research.”

It’s also been a boon to her lab. “We’ve developed new techniques for testing, and for crystallization. And all my students are trained on it, which is a plus when they go out into industry.”